FEATURES

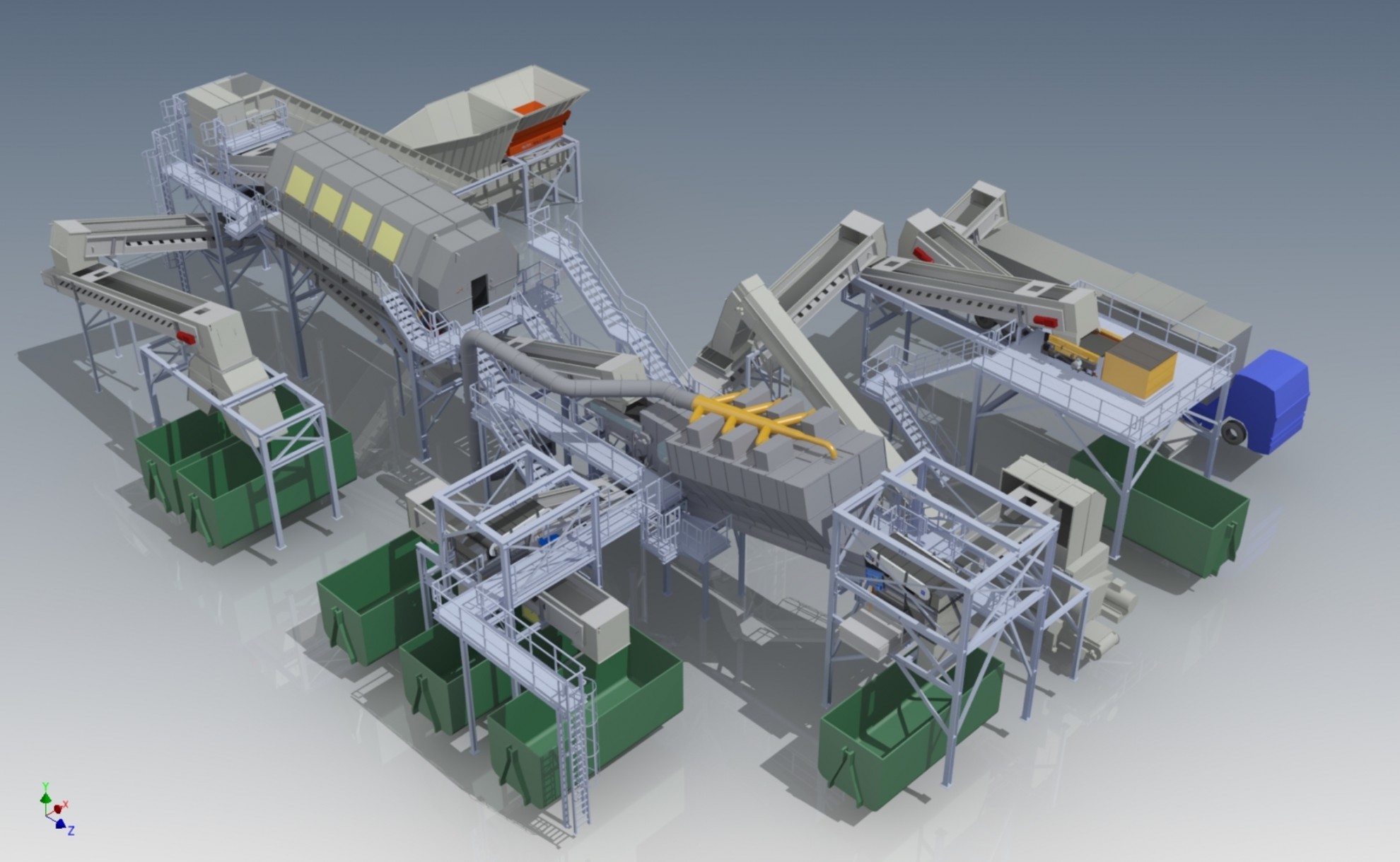

After biological phase, the material has to be subjected to a mechanical separation treatment in order to discard low calorific fraction and obtain a final SRF with a suitable quality. Entsorga propose a flexible mechanical refinement system, allowing the production of a high quality SRF. This refining line is the Entsorga’s Prometheus™ technology.

Prometheus™ consist in a very efficient set of different equipment that lead to the increase of the calorific value by sorting out the unwanted fractions. The sequence and the number of machines mostly depends on the quantities and on the waste composition.

At the end of the process you get three main streams of material:

– High quality alternative solid fuel SRF

– Stabilized residual waste (fine & heavy, with residues of organic fraction and aggregates) for landfill

– Recycled material (ferrous metals, non-ferrous and PVC)

ADVANTAGES

Entsorga’s Prometheus™ system allows:

- maximizing yield and quality of the alternative fuel produced

- minimizes residual waste to be landfilled (15-20%)

- optimizes recovery (3-10%) of recyclable materials (ferrous metals, aluminum, copper, brass and plastic materials)

- minimum electrical consumption

PROMETHEUS SOLUTIONS FOR THE MECHANICAL REFINING OF ALTERNATIVE FUELS

PRIMARY SHREDDER

To homogenize the size of the waste

AIR GRADER

To discard the high density fraction, from low calorific

EDDY CURRENT SEPARATOR

To recover non-ferrous metals

GRANULATOR

To adapt the SRF to the size specifications required

ROTATING DRUM SCREEN

To separate the fine fractions that will be used as landfill cover

MAGNETIC SEPARATOR

To separate ferrous metals

FALCON

To remove plastics with chlorine.